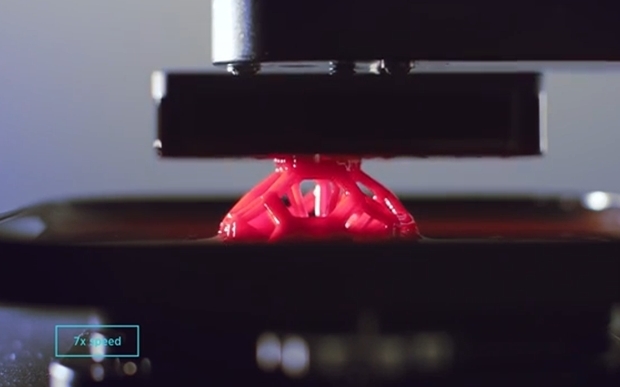

Continuous liquid interface production: Photo: Carbon3D.

A revolutionary new form of 3D printing, up to 100 times faster than current methods, has been unveiled by US researchers.

Traditional 3D printing, or additive manufacturing, relies on a painstaking process of layer-by-layer construction. Particles of plastic or metallic agents are "glued" together to slowly build up structures, ranging in size from tiny components to whole houses.

But as Dr Chris Smith of the Naked Scientists told This Way Up's Simon Morton, the main drawback to the current technology is that it's painfully slow.

Writing in the journal Science, a team of researchers at the University of North Carolina and the company Carbon3D claim to have developed a process called CLIP or continuous liquid interface production. The researchers say the method is up to 100 times faster than current methods, raising the prospect that it will be able to achieve in just a few minutes what traditional 3D-printing technologies would take hours to make.

"In our system," said Joseph DeSimone who led the study, "we have a puddle of 'polymerisable' liquid sitting above a window. A 'movie' of ultraviolet light shines through the window and causes the polymer to set in a shape corresponding to where the UV falls. Oxygen permeating through the window stops the polymer setting against the window, and we draw the 'printed' object out of puddle as we go."

Dr Smith says the possibilities for this technology could be enormous. "The immediate applications they are talking about are things like fancy sensors so you could make much more sensitive, much more effective but cheap sensor devices, you could make very effective lab-on-chip devices to do diagnostics, or chemical reactions and tests and even things to implant in the body, or drug delivery vehicles...The thing that is holding up making these things at the moment is the speed so they've cracked that one."

Meanwhile, inspiration for the new process came from an unlikely source; the film Terminator 2 and a scene where a robot assassin emerges from a bath of liquid!